3 Simple Techniques For Premier Aluminum Llc

Table of ContentsAll About Premier Aluminum LlcPremier Aluminum Llc Fundamentals Explained9 Easy Facts About Premier Aluminum Llc DescribedThings about Premier Aluminum LlcWhat Does Premier Aluminum Llc Do?

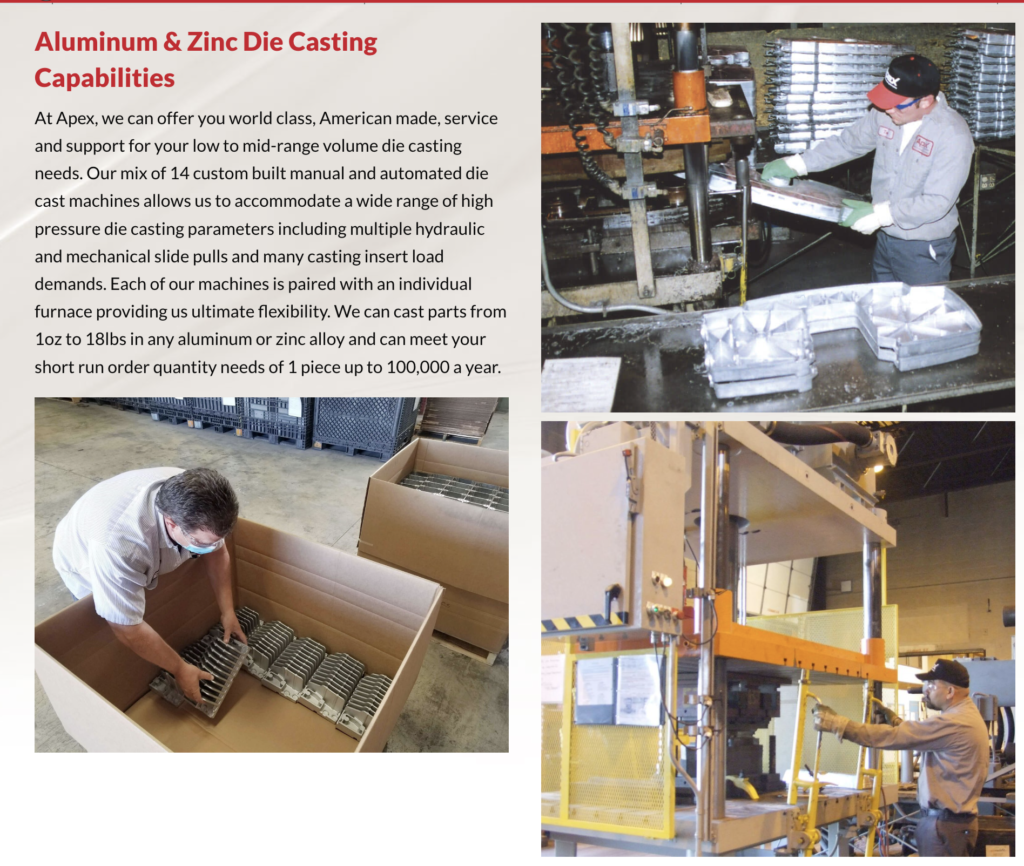

When choosing a light weight aluminum shop for your production demands, it's crucial to study numerous aspects. Among one of the most essential aspects to think about is the experience and proficiency of the shop. Choosing a factory who has the right knowledge of the aluminum casting process, and the portfolio to show for it, aids to have a successful end result for your project.Having the experience and industry expertise to craft your spreadings for ideal manufacturing and high quality results will streamline the task. Making light weight aluminum castings calls for a complicated set of procedures to accomplish the best outcomes. When selecting a brand-new aluminum foundry to companion with, guarantee they have considerable industry experience and are educated concerning all aspects of the light weight aluminum casting procedure: style, production, material analysis, and product screening.

The factory ought to additionally have a proven record of supplying exceptional items that fulfill or exceed client assumptions. Quality control should additionally go to the top of your checklist when choosing a light weight aluminum foundry. By working with a qualified factory who follows the criteria for top quality control, you can protect the honesty of your product and guarantee it meets your requirements.

The Facts About Premier Aluminum Llc Revealed

This specific process can be automated and duplicated. Different components that really complicated forms can be manufactured utilizing this procedure. Large volumes of parts can be created in just a brief period of time. Prior to you start searching for a reputable light weight aluminum pass away caster, there are some crucial things that you need to do.

You need to ask on your own what sort of aluminum pass away castings you call for. After establishing what you require, you need to specify the specifications of the aluminum pass away castings you need. Determine the weight, density, size, and other specifications of the light weight aluminum die-cast you call for. It would certainly likewise be better if you could attract and show all the dimensions of the light weight aluminum die-cast.

After having this info, you can start investigating aluminum die-casting manufacturers. You can do this by just typing the key phrase" Aluminum pass away casting suppliers" on the Google search engine.

Some of the inquiries you require to ask on your own are whether they have experienced and my sources well-trained operators, how much time their company has actually been in procedure, or if they have some accomplishments. You can often obtain the responses to these inquiries from the producer's web site. You can look into other internet sites or outside resources to verify if the info supplied on the producer's website is genuine.

The Of Premier Aluminum Llc

One more thing you have to take into consideration is the manufacturer's ability to generate light weight aluminum die-casting products. In other words, the quantity of items the manufacturer can generate at a provided time. Several of the vital concerns you require to ask on your own are whether the manufacturer can create a greater quantity or can the supplier meet your demands.

(https://www.huntingnet.com/forum/members/premieraluminum.html)What happens if your firm calls for 10,000 pieces of certain machine components from the producer within one month? You got this amount; nevertheless, the maker can only generate 5000 items of these device components within one month (Foundry). Consequently, you won't have the ability to get the quantity that you purchase on time

The Premier Aluminum Llc Statements

It is crucial that you ought to inquire if the supplier is carrying out an in-house tooling procedure. Additionally, you have to ask the maker just how much the cost of in-house tooling is. The in-house tooling procedure, which allows you to develop distinctive styles and shapes can be an added cost.

This element straight associates with the manufacturer's manufacturing capability. Aluminum Castings. You have to look for a producer that can make sure quicker distribution of products.

This suggests that there are several choices that you can select from. Today, client needs keep on transforming. It appears that consumers are looking for an excellent combination of high quality, cost-effectiveness, and sturdiness. That is why it is substantially advised that you should select a supplier that can generate different sorts of light weight aluminum die-cast products.

Premier Aluminum Llc Can Be Fun For Everyone

Frequently, these aluminum die-casting items will call for some decorations, machining, or completing touches. Having this in mind, you need to seek a supplier that can implement a range of additional ending up jobs when die casting is done. Some instances of finishing procedures include Chromating, CNC Machining, Sandblasting, Powder finishing, Anodized, E-coating, Wet paint, Plating, and much more.

Pass away spreading is one of the most affordable, precise, and protean production processes in the world moment. The procedure entails fitting molten significance, under stress, into a relevant die (planet), and formerly solidified it can be expelled and finished (if needed) in a variety of ways.

Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!